Reducing Harvest Losses in Soybeans

Field Facts written by Steve Butzen, Agronomy Information Manager

Field Facts written by Steve Butzen, Agronomy Information Manager

Minimizing soybean harvest losses can mean substantially higher yields and profits. Extension agricultural engineers suggest that good harvest practices can reduce losses to near 3%, or only 1 to 2 bu/acre. However, delayed harvest or poorly adjusted equipment can result in losses of 10% or more. Since soybeans dry very quickly, close monitoring of grain moisture is required for timely harvest. In addition, combines must be properly adjusted, frequently checked and carefully operated to minimize losses.

Soybeans should be harvested the first time they reach 13-14% moisture. Moistures above 13% incur a price discount, but moistures below 13% result in less weight at the elevator. The loss of saleable weight can be more substantial than typical discounts for wetter grain, so growers should avoid delivering overdry soybeans. In addition to lost income, harvest losses are also increased when soybeans are harvested too dry.

Soybeans dry very quickly after reaching maturity. At physiological maturity (R7), grain moisture is over 50%, but a harvestable moisture of near 13% can be reached in as little as 2 weeks under good drying conditions. In order to time harvest perfectly, it is necessary to monitor soybean drying very closely. At full maturity (R8), 95% of pods have reached their mature pod color. From this point, only 5 to 10 good drying days are needed before harvest. Begin checking grain moisture before all the leaves have dropped off all the plants, since various stresses can cause soybeans to retain some leaves. It is not uncommon to see a few green leaves and stems on some plants after the pods are fully ripe and the soybeans are dry enough for harvest.

When harvest is delayed, a number of potential losses may occur, including increased tendency to shatter. Soybeans at harvest stage lose and reabsorb moisture readily, and after several such cycles of wetting and drying, are predisposed to shatter. In addition, delayed harvest often results in losses from increased lodging and reduced grain quality.

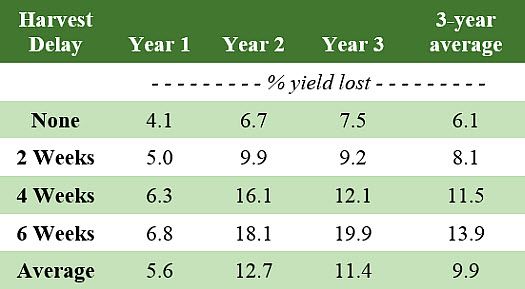

A study conducted at the University of Wisconsin investigated the effects of delayed harvest on soybean field losses. In total, 2 varieties from each of 3 maturity groups were grown in each of 3 years at Arlington, Wis. Initial harvest for each maturity group began 3 to 7 days beyond the R8 stage (full maturity). Other plots were left in the field for periods of 2, 4 and 6 weeks beyond the first harvest date. Yield losses as a percent of total yield are shown below:

Table 1. Effect of harvest delay on soybean field losses.

Source: University of Wisconsin

Yield loss was greatly affected by year. In year 1, field losses after 2 to 6 weeks of harvest delay were only slightly higher than normal field losses with no delay. But losses due to harvest delay in both years 2 and 3 were over twice that of year 1. Losses increased with weeks of delay in all years tested.

Preharvest, shatter and stem losses increased with harvest delays, but stubble and threshing losses remained constant across delays. Gathering unit losses accounted for 60% of total losses.

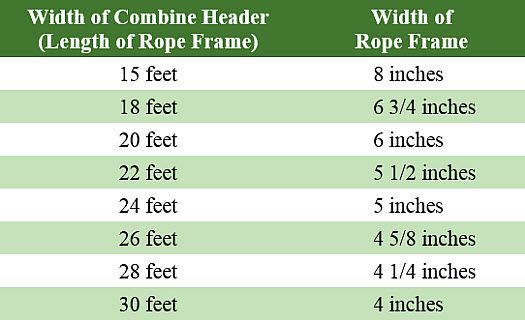

Four soybeans in a 1-foot-square area are equal to a 1 bushel loss per acre. Harvest losses should be checked in front of the combine, behind the header, and in back of the combine to pinpoint causes of loss. Ag engineers suggest checking losses in a rectangular area across the entire width of the harvest swath. A 10-square-foot rectangle is suggested as a standard size. Forty soybeans in a 10-square-foot area translates into a 1 bushel per acre loss. A 10-square-foot frame can be built out of rope, with small metal stakes (heavy wire or nails) at the corners to insert into the ground. The length of the frame should be the width of the combine header. The width of the frame needed to equal 10 square feet of area is shown below:

A convenient means of measuring losses is to stop the combine and back up about 20 feet. Losses are determined in 3 areas: in the standing soybeans, behind the combine, and 5 to 10 feet behind the standing soybeans. Set the frame across the entire swath width in the standing soybeans. Soybeans, pods, or broken stems on the ground here represent preharvest losses. Count the number of soybeans shelled and in pods on the ground within the frame. Forty soybeans is equal to 1 bushel loss per acre.

Now move the frame to an area behind the combine and count again. Be sure to sort through all crop residue to reveal shelled soybeans and unthreshed pods beneath. Also count soybeans in pods on stubble. These soybeans behind the combine represent total losses. The difference between total losses and preharvest losses represents harvesting losses.

Harvesting losses can be further divided into "gathering" or "cutterbar" losses and machine losses, by checking just behind the standing beans. To make this measurement, set the frame across the entire swath width about 5 to 10 feet behind the standing soybeans. Count and record the number of individual soybeans within the frame that are shelled and in pods, including stubble. This count minus the preharvest count equals the gathering loss. Machine loss is calculated as follows:

| Total loss - preharvest loss - gathering loss = machine loss |

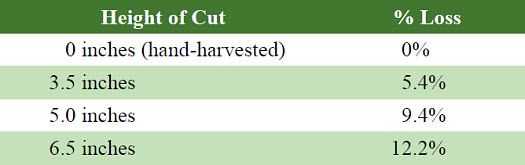

Though the type of equipment used can impact harvest loss, all equipment must be properly adjusted and carefully operated to minimize losses. Soybeans that never get inside the combine can account for 80% to 85% of harvest losses. These losses occur due to shatter or lost stalks at the header or left on stubble below the cut-height. Other losses occur due to improper threshing and separation at the cylinder and screens. Harvesting losses can be minimized with proper maintenance and adjustment:

Source: Iowa State University

Pedersen, P. 2006. Combine setting for minimum harvest loss. Soybean Extension and Research Program, Iowa State U.

Philbrook, B.D. and E.S. Oplinger. 1986. Soybean field losses as influenced by harvest delays. Agron. J. 81:251-258.

The foregoing is provided for informational use only. Please contact your Pioneer sales professional for information and suggestions specific to your operation. Product performance is variable and depends on many factors such as moisture and heat stress, soil type, management practices and environmental stress as well as disease and pest pressures. Individual results may vary.

PIONEER ® brand products are provided subject to the terms and conditions of purchase which are part of the labeling and purchase documents.